Laminating with Beil

For more than 5 decades, BEIL is THE partner for plastics in the workshops of orthopaedic technology and orthopaedic shoe technology. Professional solutions on customised materials as well as practise-oriented applications and processing techniques makes BEIL products a “must have” of every workshop.

Vacuum laminating

When laminating with vacuum technology you are able to fabricate thin-walled laminates with low weight and high shape retention. Between the separating films the reaction resin is brought together with reinforcing materials by means of vacuum. The products of BEIL allow many design possibilities due to the variation of different fibre and resin types, orientation and number of layers of reinforcing materials.

Open Laminating

In the hand laminating process, the reaction resin is easily and quickly applied with a brush on the reinforcing fibres and cures fast. Our polyester resin BKF Polyfest HQ and epoxy resin BKF EpoxCarbon are particularly suitable for this.

Variety of Resins

You will find the right laminating resin for every workpiece.

BEIL offers a wide range of acrylic resins, epoxy resins and polyester resins. Additional application notes are available in our Product Information in the Download area.

Reinforcing Materials for Laminating

BEIL offers a wide range of appropriate reinforcing materials for the different resin systems in the lamination technique. All products were especially selected to meet all requirements of the orthopaedic technology and orthopaedic shoe technology.

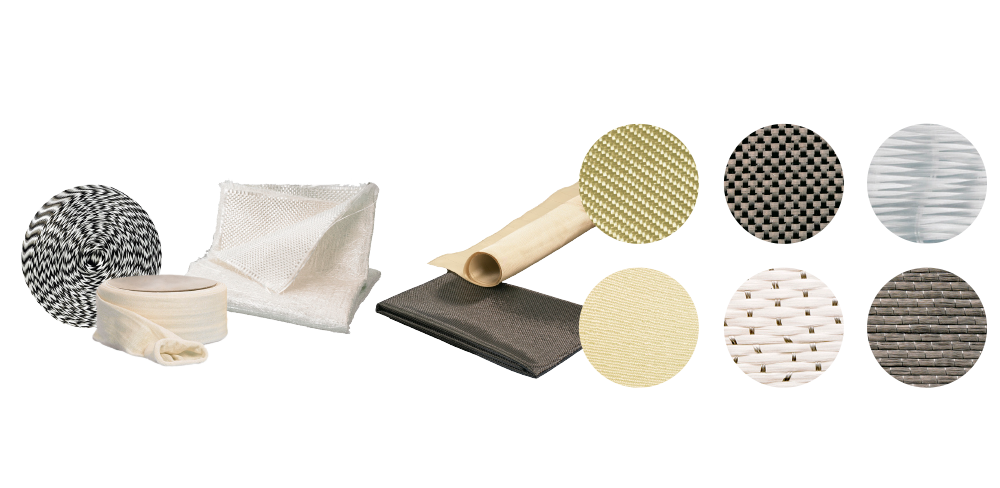

You can select between glass, carbon and aramid/Kevlar fibres. Combinations of glass and carbon fibres are also available.

Fabrics or mats in various weights are suitable for extensive laminates. Reinforcing tapes, however, strengtheni the laminate. They are available in various widths and types of weave. Our braided tapes and stockinettes are suitable for a wide range of applications in the lamination technique. These materials can be pulled over different circumferences without creases due to stretching and compressing.

PVA Film Sleeves

BEIL has always been THE manufacturer of machine-made PVA film sleeves. Due to strict requirements in our quality control, the very high and consistent quality is assured.

PVA film sleeves have a conical form and are available in several lengths, widths and two different thicknesses. The required length and width results directly from the model form, the thickness of the material is chosen with regard to the intended use of the film sleeves. In the orthopaedic shoe technology, we recommend to use the thicker film sleeves of 0.10 mm thickness. If your required size is not included in the product range, we can produce your PVA film sleeves according to your individual dimensions.

We are happy to take some time for you

Our Technical Service will be pleased to answer your questions and offers you advice and support.

Please contact us any time at: